Both the International and Uniform Plumbing Codes require that fixture traps be vented to protect against loss of trap water seal. Ventilated plumbing traps have been required since the early 1900’s. Venting requirements are a fairly recent requirement given the thousands of years we have been assembling plumbing systems. It is the proper venting of sanitary sewer systems that has allowed plumbing fixtures to be safely located inside living areas.

Without a vent, the fixture trap water seal can be lost due to siphonage or backpressure. Sewer gases in the living space is about far more than just the noxious odors, these gases contain airborne bacteria. Sewer gases entering the living spaces can have deadly consequences. A 2003 SARS (Severe Acute Respiratory Syndrome) epidemic in Hong Kong was found to have been partially the result of dry plumbing traps. Improper venting resulted in 321 people becoming infected with the SARS virus and contributed to 65 deaths.

Proper venting prevents trap siphonage, allows backpressure to dissipate and allows for air circulation within the system.

IRC 3101.2.1 Venting required. Every trap and trapped fixture shall be vented in accordance with one of the venting methods specified in this chapter.

UPC 901.2: Vents Required: Each plumbing fixture trap, except as otherwise provided in this code, shall be protected against siphonage and backpressure, and air circulation shall be ensured throughout all parts of the drainage system by means of vent pipes installed in accordance with the requirements of this chapter and as otherwise required by this code.

IRC 3101.2 and UPC 901.2 mandates traps for all fixtures. The codes describe what the vent system must accomplish. The UPC covers commercial applications and provides exceptions for certain commercial installations such as interceptors, soda fountains, bars, etc. See Section UPC 901.3

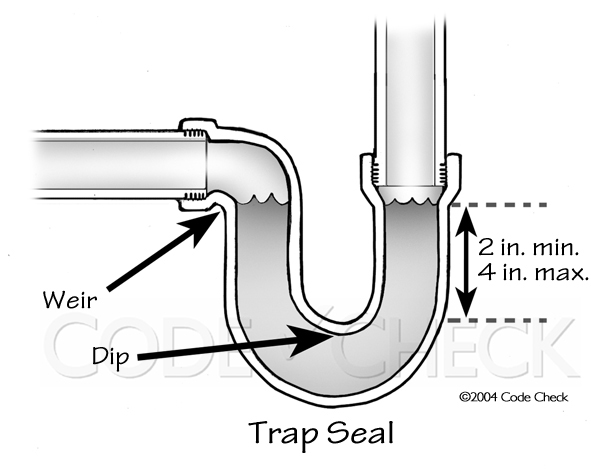

IRC 3101.2 Trap seal protection. The plumbing system shall be provided with a system of vent piping that will allow the admission or emission of air so that the liquid seal of any fixture trap shall not be subjected to a pressure differential of more than 1 inch of water column.

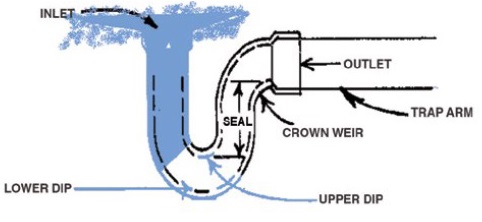

UPC 901.3 Trap Seal Protection: The vent system shall be designed to prevent a trap seal from being exposed to a pressure differential that exceeds 1-inch water column on the outlet side of the trap. (Fig 1)

Fig 1: Atmospheric Pressure Must Be Maintained

on Both Sides of Trap Seal

IRC 3101.2 and UPC 901.3 tells us that atmospheric pressure must be maintained on both sides of the trap seal. This citation tells us the maximum air pressure differential that a trap seal can be subjected to. These pressure differentials are what drive the 2-in minimum and 4-in maximum trap weir water level (IRC 3201.2 and UPC 1005.1).

What Causes Siphonage?

Siphonage generally occurs under two conditions. The water may be siphoned out of the trap if there is sufficient negative air pressure (think suction) on the drain side to draw the water out of the fixture trap. Negative air pressure can occur as water flows rapidly downward through a drain stack. The water flow draws air in behind it as it drops. When a slug of water flows past an unvented branch that is connected to that stack, it can pull air from the branch creating a pressure drop. If there is enough negative air pressure, it can syphon the water out of trap seals on the branch. Negative pressure may also occur when a fixture drain is discharged such as draining a filled sink. The discharge from a fixture can result in a negative pressure condition that can siphon an adjacent unvented or improperly vented trap. Properly venting of traps prevents these negative air pressure conditions and protects the trap water seal.

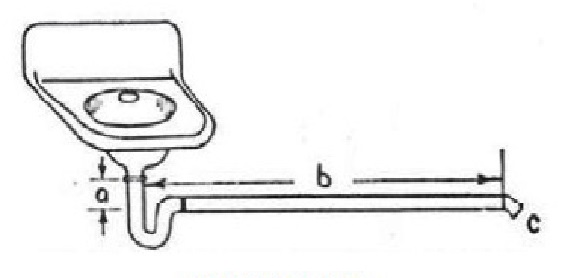

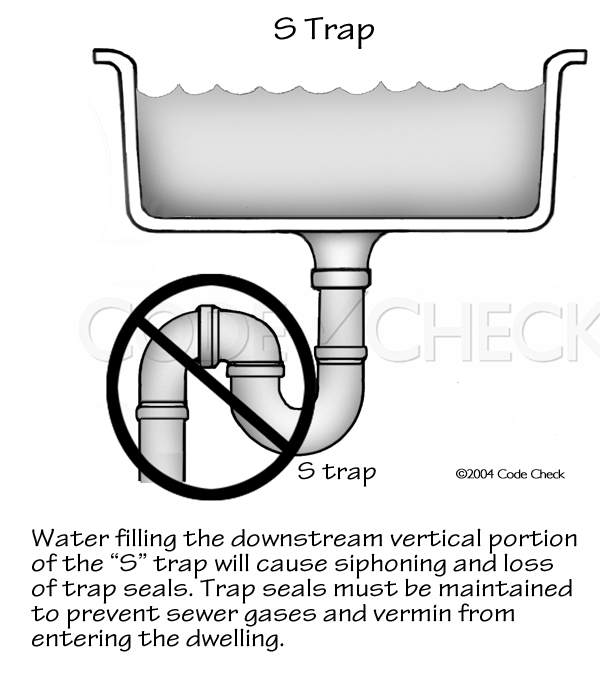

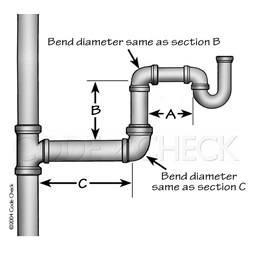

A fixture may also siphon itself. This is referred to as self-siphonage. Self-siphonage can occur if there is an unbalanced water column in the trap Self-siphonage may also be the result of fluid velocity, or momentum pull (F2). Fast moving liquids exert “pull” on the trap water seal. Some examples would be trap arms with excessive slope, S-traps (Fig 3), trap arms that “step down to the vented connection/inverted trap (Fig 4), etc. The water momentum creates suction on the trap seal and “pulls” it along resulting in a loss of seal. That is why these configurations are prohibited unless the fixture traps properly vented to prevent self-siphonage.

Fig 2: Excessive Trap Arm Length Can Cause

Momentum Pull/Syphonage

Fig 3: S-Trap Can Syphon Fig 4: Inverted Trap May Self-Syphon

What is Backpressure?

When positive air pressure (increase or positive pressure above atmospheric) occurs in the in the drainage system, this is referred to a backpressure. When water flows down a drain stack, it pushes air ahead of the liquids. The force of the falling liquid pressurizes the air flow. The air pressure will try to equalize and dissipate through the sewer drainage system. A properly vented drain system allows backpressure to dissipate and vent to the exterior. If air pressure builds, it can equalize by blowing air bubbles through water trap seals. In extreme cases, it can literally blow the water seals out in improperly vented systems (Fig 5). Obstructions in the drain system, such as backwater valves may increase the effect of backpressure. .

Fig 5: Trap Seal Blow Out Due to Backpressure

Hydraulic jump is a condition where the liquid flow rate exceeds the capacity of the pipe. The excess flow condition may cause the water level in the pipe to rise and block the air path above the liquid level. This closure may create a positive air condition and results in the pressure equalizing through nearby improperly vented traps. Hydraulic jumps may be more pronounced at horizontal junctions where one branch flows into another and at the base of drainage stacks (Fig 6).

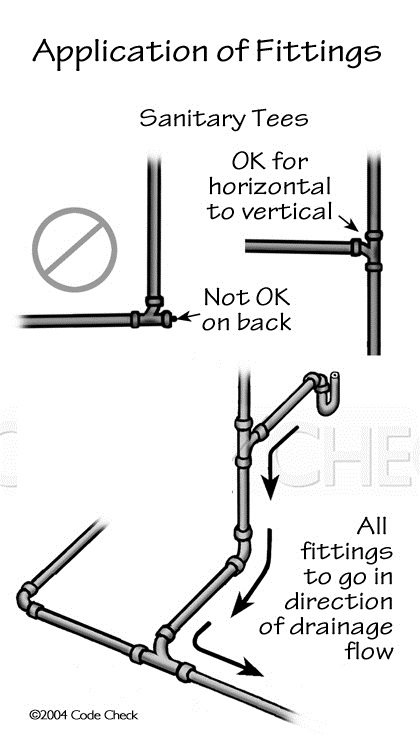

Fig 6: Correct Fittings Ensure Proper Flow

Hydraulic jump is a big reason why that properly installed transition fittingss are so important. Improper fittings, such as a sanitary tee on its back or side may cause jumps to occur due to ineffective fluid flow. Proper venting allows hydraulic jump backpressures to be dissipated to the exterior and protects the trap seals. (IRC 3005.1 and UPC 706)

Why is Air Circulation Important?

IRC 3101.2 and UPC 901.2 require that air circulation be provided throughout all parts of the system. This means that air flow cannot be restricted in the drainage system. This includes the building drain, building sewer, and public sewer. Proper venting ensures that atmospheric pressure will be equal on both sides of all trap seals regardless of flow conditions. As with traps, the pressure differential should not exceed plus or minus one-inch water column across the system.

Building traps are prohibited (unless specifically allowed by the AHJ) because they block air circulation between the building drain and sewer (IRC 3201.4 and UPC 1008.1). Building traps are not generally used because the storm system is separate from the sewer system in most areas. San Francisco, CA being an example of an exception. Storm system manhole covers are not sealed and allow the storm system air to equalize to atmospheric pressure. Sewer manhole covers are typically sealed and do not provide free air circulation in the sewer system. They use the vents in the building for air circulation and equalization. In UPC 1008.1, if a building trap is allowed, there must be a relieving vent upstream of the building trap (on the house side). Per UPC 904.1, there must also be a vent downstream of the building trap to allow air circulation and equalization in the public sewer or private sewage disposal system.